FAQ'S, LATEST NEWS!, QUESTIONS & ANSWERS, STEEL PREPARATION, TIPS & TRICKS

MILL-SCALE REMOVAL

QUESTION: Re: MILL-SCALE REMOVAL & DROSS/SLAG REMOVAL…

I am wondering how you guys clean & prep your Hot-Rolled Steel for paint / powder / patinas, dyes or whatever you finish with…….

So far I have been using a “flap” disc on my grinder which works ok but I go through a LOT of flap discs. I tried wire wheels and the finish is better and it’s quicker but the resultant “porcupine” look doesn’t suit me

I have a ton of reasons for avoiding the Muriatic Acid, kids pets, -30c winters to name a few……

I figured a drum sander would be the way to go, but that seems like it may not work as well as I had hoped for..based on other posts… sand blasting is I guess a possibility. i have a small cabinet blaster, but not big enough or powerful enough (compressor wise) so I am considering flap disc followed by drum sander…….or possibly building a “wire wheel machine”

So please, aside from the acid, what do you guys do??? I also have to get my cuts better so there is less dross! (Name omitted by request)

ANSWER by Bill:

Check out this post on PLASMASPIDER for an alternative to flap-discs on an Angle-Grinder. I use mine all the time & it’s well worth the investment. viewtopic.php?f=81&t=12130&p=66267&hilit=flex+burnisher#p66267

Media Blasting will lead you to the poor-house. It takes too long (waaaaay too long) and it leaves a matte finish, which then has to be brightened up, so you’ve gained nothing. Disclaimer: The FLEX® Burnisher is not a good option for removing mill-scale. It’s better than a flap-disc or an AVOS® Disc, but the abrasive will “load-up” with the mill-scale, which is just a bunch of oxides & scale that’s actually harder than the carbon steel beneath it.

Have you ever puked? You know that burning sensation in your throat, mouth & nasal passages? It’s Muriatic Acid. Technically, it’s Hydrochloric Acid, (HCl), which is the same thing as muriatic acid. The Muriatic Acid you buy at the hardware store is usually diluted to 31%. Hydrochloric Acid is the main acid in our stomachs. It’s not that dangerous if handled respectfully. There’s a LOT Worse Acids out there, and Muriatic Acid is a necessary evil when dealing with heavy rust on older steel or Mill-Scale on new HR Steel. Once you’ve mixed it 1:1 or 1:2 (see below), with water, there is no appreciable odor, (I can’t smell it at all at either mix ratio).

The main thing to remember is this: Keep Your Tank Covered!! The off-gassing of the Hydrochloric Acid will lay down a rust film on any ferrous metal within 50 feet! If you don’t have a cover or don’t want to make one, buy a few hundred ping-pong balls and cover the entire surface of liquid, one-layer thick. You can find ’em online really cheap. That will prevent >90% Off-Gassing. They make special HDPE Plating Tank Balls, but they’re really expensive. Any hollow ball (with the exception of wiffle balls), that’s made of any plastic will work. Styrofoam balls won’t work…too porous. The smaller the balls (spheres) that you use, the better, as the smaller balls minimize negative space. Bubble wrap would work, but may tend to bunch up and shift in a breeze. You could thread some tie-wire through the edge to make the bubble-wrap sheet more rigid.

At some point, maybe now…you’re realizing that the old saying, “Time is Money” is really true, and you will try muriatic acid and wonder why you waited so long. Don’t buy the unscented variety of muriatic acid. Too expensive & too weak.

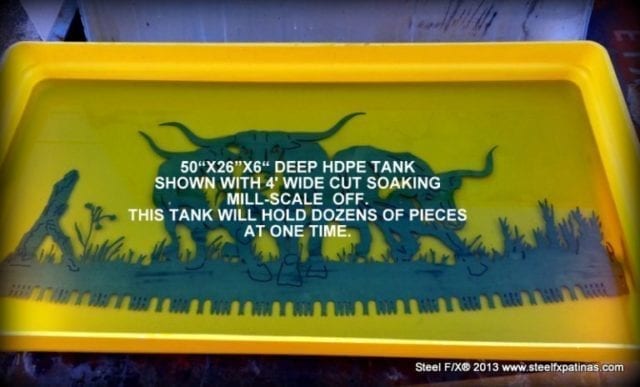

btw…my tank is a Rubbermaid® HDPE, heavy-wall, 250 Gallon Water Trough, Oval in shape. I only have about 4″-8″ of liquid in it, I don’t fill it to capacity. I started using that because I could fit my larger pieces in it. You could make a nice tank from 4″X4″ lumber & a shower liner or ‘in-ground’ water-feature liner. Those liners are not too expensive & are totally impervious to the acid. Pond Liners are so heavy that you could actually cut a piece for the top/cover, too. When your acid bath gets crusty and gross (and it will), add some water & tip it over in the dirt. It won’t harm groundwater, as hydrochloric acid is actually a gas, suspended in water. It will “disappear” in a few minutes. Don’t empty your tank on concrete, though…unless you want the ‘rusted concrete look’. (Some folks pay a LOT to get their concrete stained)!! And, no need to neutralize with CaCO3 (Calcium Carbonate), a.k.a Lime or NaHCO3 (Sodium Bicarbonate a.k.a Baking Soda.

You may see a few posts where guys are dipping their steel pieces in a baking soda/water bath after removing from the acid bath. Totally unnecessary. Absolute Waste of Time. ZERO (0%) Acid will remain on your steel after rinsing with water. Zero! Just remove your steel pieces one at a time, rinse both sides w/ plain water & immediately force-dry with clean, dry, oil-free compressed air & set aside, ready to be shined up. If you’re using a rusting patina, there’s no need to shine the steel, just as long as it’s good & clean, you’re ‘good to go’.. Thanks! Hope this info helps a little.

Bill

p.s. I can tell you from firsthand, everyday personal experience, using a multitude of Dry Acids, and 7-8 Different Liquid Acids at 99% Purity/Strength, I’d rather work with the Liquid Acids ANY DAY over the Dry Acids. Dry Acids and Dry Oxidizers are dusty. When you inhale or inadvertently get any of that dust on your lips, tongue or eyeballs, it is F-ing Miserable! With a Capital “F”! And the ‘wash-up’ & recovery time is considerably longer than what it would be if you were subjected to a little splash of a liquid acid.

Note: My patina’s acid content, in almost all cases, is less than 1/10th of 1%. A few are measured in PPM, and a few others, including my Dyes & Stains Have Absolutely No Acid At All. I don’t make or sell a single patina, in either liquid or gel form that will burn your skin.

Liquid Chemicals (Acids in Particular), in a Lab or Production Setting are much, much safer to handle & be in the proximity of, than dry acids. And, when you consider that you can remove ALL Mill-Scale from Both Sides of a piece of HR steel in as little as 30 Minutes, there’s no reason to use dry acids, even if they work faster. GRIME GIT’R™ is a Great De-greaser & will also remove mill-scale. It is just the right amount of Concentrated Phosphoric Acid & Distilled Water, with a Surfactant & Preservative. I sell it at my cost to manufacture plus 10%. And, how’s this for high-pressure sales?….I prefer Muriatic Acid for mill-scale removal. One Reason Only: It Works Faster.

Soaking Hot-Rolled Steel in Muriatic Acid & Water, Mixed 1:1 (Equal Parts), or Even 1:2 (1 Gallon Muriatic Acid to 2 Gallons of Water), Will Also Remove 99% of Your Dross (Slag), if You Leave the Steel Submerged for 24-36 Hrs. (Sometimes Less Time, Depending on the Dilution Rate of Your Acid Tank).

Please let me know if any of you reading this have any additional questions or would like to comment. Comments on my posts are always welcomed & encouraged.

Thanks again…Bill