FAQ'S, LATEST NEWS!, QUESTIONS & ANSWERS, STEEL PREPARATION, TIPS & TRICKS, Uncategorized, UNIQUE FINISHES

Oil Removal from Steel?

ANSWER:

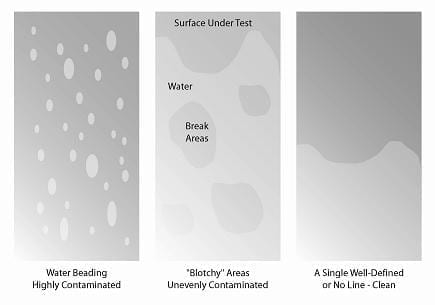

Is It Clean? – Oil and Hydrophobic Films – Water Break Test

The last thing you want on a surface that is to be plated, painted or otherwise coated with something that needs to adhere to that surface is a film of residue that prevents that adhesion. The water break test is a simple, quick and usually non-destructive test to test for hydrophobic films. The test is most frequently applied on freshly cleaned metals including steel, aluminum, brass and other metals that, in a totally clean state are hydrophilic.

Although the test is usually applied on large flat surfaces like sheet metal, it can, in somewhat modified form, also be applied to some surfaces with relatively smooth surface geometry. It is not applicable on parts with complex geometry including acute angles and undercuts for example.