FAQ'S, QUESTIONS & ANSWERS, TIPS & TRICKS

RUST F/X™ Tip:

QUESTION:

Hello Bill,

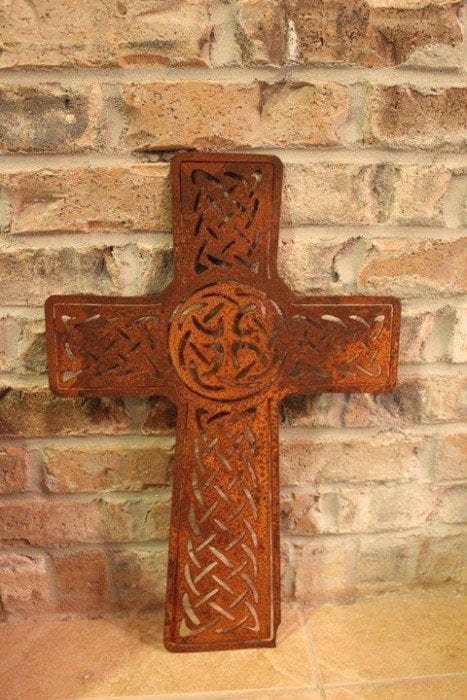

I have been using your RUST F/X and overall have been very pleased with the product. I have been getting inconsistent results though. I am using the product on 14 gauge steel that has been laser-cut. When I get the steel back from the laser-cutter, I clean the pieces with dish soap and water to remove the greasy film. I let dry and then spray with your product. During the summer, I spray them outside and get a nice evenly rusted finish. During the winter, I spray them in the basement and then get a finish that has a lot variation in color and texture. I get black areas, some areas rust much faster than other areas and also the texture ranges from smooth to the usual “sandy texture” rust finish. Am I do something wrong? How do I get a more consistent finish.

Thank you for your help!

Mark F.

ANSWER:

- Keep the area you’re working in as warm as possible w/o running up your electric bill too much. A space heater or infrared poultry (brooding) lamp, directed at the piece would be helpful.

- Always try to keep the surface wet for the first hr. or two. Repeated mist applications of the RUST F/X™ (3 or 4) is helpful. Subsequent misting can be done with plain water, but not to the point of ‘run-off’.

- Work with the piece horizontal whenever possible.

- Oxygen (Air, Chemical, Environmental)

- Moisture (Humidity, Rain, Water)

- Heat (Natural or Added)